The new generation of Caterpillar excavator CAT320 has a good performance, its operation parameters configuration, has commendable characteristics, for users, the operation needs to meet the past, the pursuit of greater input and output is the most important.

Caterpillar New Generation CAT320 Excavator

Total width (mm): 3170

Minimum ground clearance (mm): 468

Rear radius of gyration (mm): 2833

Track width (mm): 3170

Total length (mm): 9531

Total height (to the top of the shed) (mm): 2960

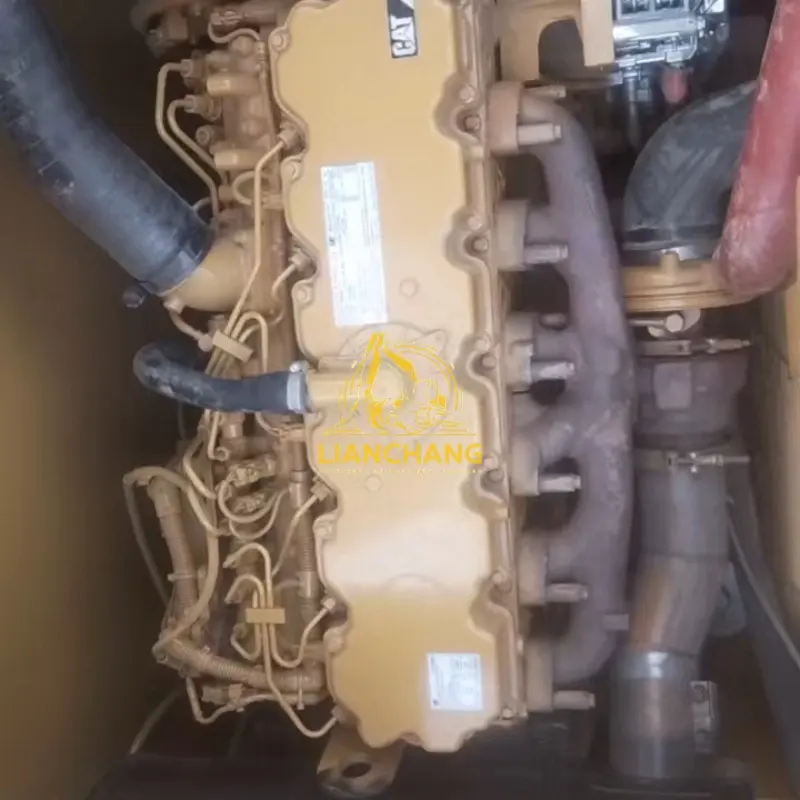

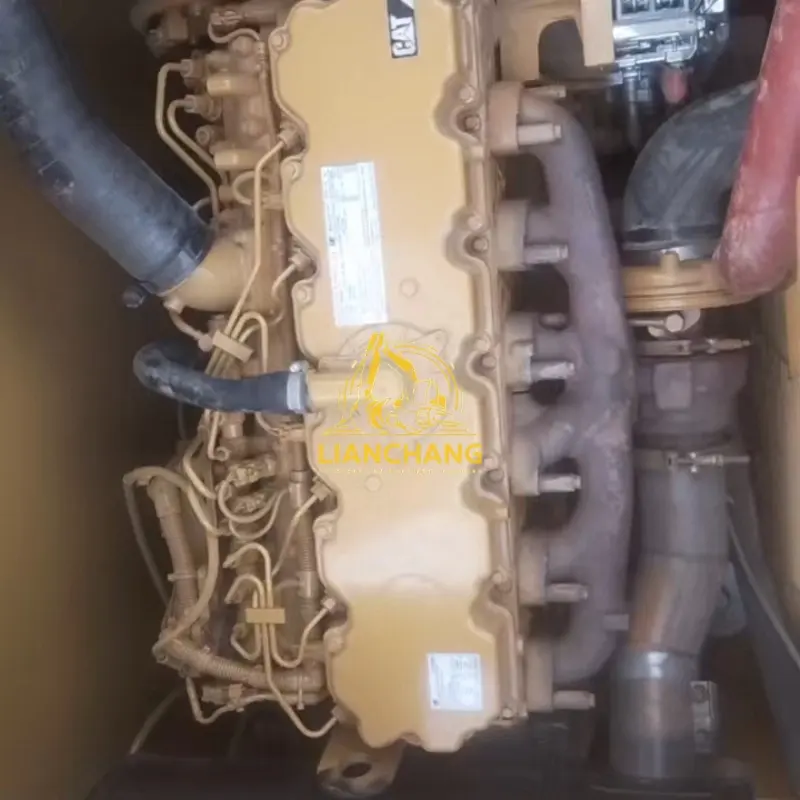

The CAT 320 excavator delivers outstanding performance and incorporates a variety of easy-to-use technologies, such as CAT GRADE with 2D, Grade Assist and Payload systems. These are factory standard equipment that can increase your operator efficiency by up to 45%. In addition to these features, it offers a new cab, longer maintenance intervals that reduce maintenance costs by up to 20%, and a powertrain that reduces fuel consumption by up to 20%. As a result, you have an excavator that is ideally suited for your medium to heavy duty applications at a relatively low cost per unit of production. Not all of these features are available in all regions. Contact your CAT agent for specific configurations available in your area. Higher performance with lower fuel consumption · Up to 20% less fuel consumption than the CAT 320D2 excavator.

Standard CAT Connect technology improves operational efficiency by up to 45% and reduces operator fatigue and your operating costs, including fuel consumption and routine maintenance. The C7.1 ACERT engine can run on biodiesel up to B20 and meets emission standards equivalent to U.S. EPA Tier 3 / EU Stage IIIA / China Non-Road III / Brazil Mar-1.

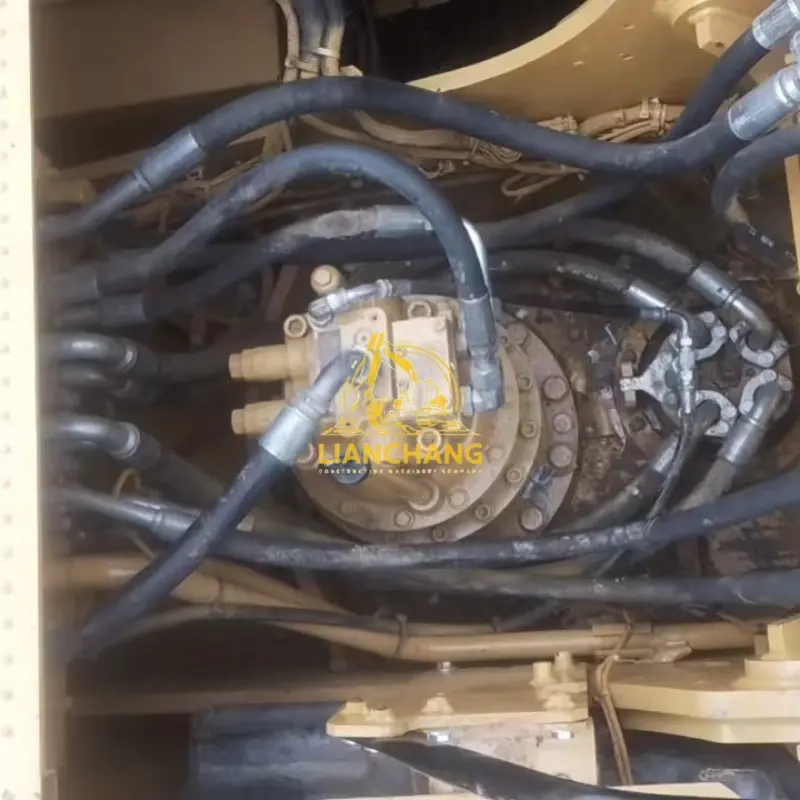

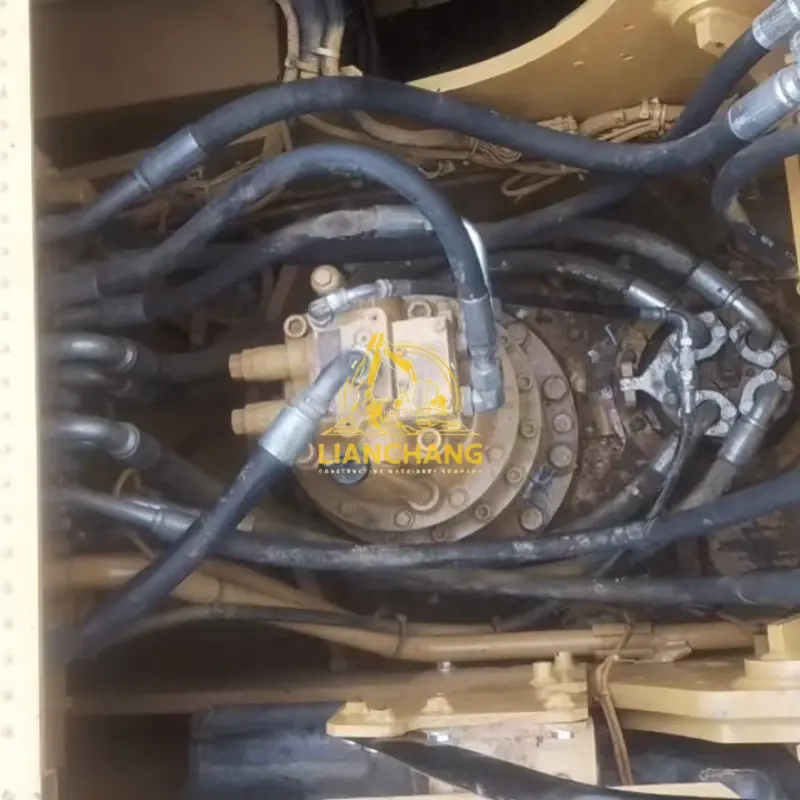

The advanced hydraulic system not only provides the best balance between power and efficiency, but also gives you the controls you need to meet your precise digging requirements.

Use power mode to match the excavator to the job; And automatically match engine and hydraulic power to your digging conditions through Smart Mode.

Auxiliary hydraulic options give you the versatility you need to work with a wide range of different CAT tooling.

Don’t let the temperature hinder your work. Excavators can operate at high temperatures of up to 52 ° C and have cold start capacity as low as -18 ° C. Additionally, an optional -32 ° C cold start kit is available through the integrated CAT Connect technology to improve efficiency and productivity with standard CAT GRADE with 2D and Grade Assist systems.

Including display-only and laser capabilities, productivity is up to 45% higher than conventional slope trimming machines.

When digging, provide guidance on depth, slope, and distance to the horizontal slope.

2D systems can be upgraded to CATGRADE with advanced 2D systems or CATGRADE with 3D systems. Standard Grade Assist:

Work continuously on slopes – easy and simple – with single joystick digging.

Set the desired bucket angle, then let BucketAssist automatically maintain the angle in slope trimming, leveling, fine leveling, and trenching applications for easy, accurate, and fast completion.

The Boom Assist keeps the tracks on the ground during lifting and hard digging operations.

In truck loading and trenching applications, SwingAssist stops the digging machine turning when it reaches an operator-defined set point, helping you save energy and burn less fuel. Standard CAT PAYLOAD on-board weighing system:

Achieve accurate target loads and improve loading efficiency with real-time payload estimates that are weighed on the go and don’t require turn-around.

Track your daily productivity, such as truck target weights and load / cycle counts.

Calibration is done in minutes. Combine the Payload upgrade with VisionLink · and remotely manage your production goals.

Upgrade to optional CATGRADE with advanced 2D system: Easily create and edit slope designs on a second high-resolution 254mm touch screen monitor.

Upgrade to optional CATGRADE with 3D system: Easily create and edit the gradient design and view the full range of movement of the front link on a second high-resolution 254mm touch screen monitor. Know the absolute position of the digging machine relative to the GPS and GLONASS systems. The machine automatically compensates for the slope and trim of the excavator caused by sloping ground conditions.

Standard ProductLink provides machine location, machine hours worked, fuel consumption, productivity, idle time, diagnostic code, and other machine data through the VisionLink online interface as needed to help you improve efficiency and reduce operational costs on the job site. Work comfortably in the all-new cab, with a choice of comfort and luxury cabs. Are equipped with automatic temperature control function.

Wide seats can be flexibly adjusted, suitable for all sizes of operators; Sitting in the luxury heated seats, it is very warm. The distance between the consoles is very wide, providing a more comfortable working environment. Easier access to and from the cab via the flippable left console (luxury cabs only). The premium viscous base reduces vibration in the cab by up to 50% compared to previous excavator models.

The controls at your fingertips are located in front of the operator for comfortable control of the excavator. · Ample cab space is provided behind the seat, overhead and in the console for easy storage of your gear. In addition, cup holders, file holders, water bottle holders and coat hooks were provided. Standard wireless USB ports and Bluetooth are available. Technology to connect personal devices and make hands-free calls. Simple to operate.

Start the engine with a button using a Bluetooth key fob, smart phone app or operator ID password. Program each joystick button with the operator ID, including response and mode; The machine remembers these programs and calls them every time you operate the machine. Navigate quickly on the high-resolution 203mm standard touch screen monitor or optional 254mm touch screen monitor, or with the help of a knob control unit. A second 254mm monitor is available for advanced grade control. Don’t know how a certain feature works or how to maintain the excavator? Access to the operator manual with a touch of your finger on the touch screen monitor.

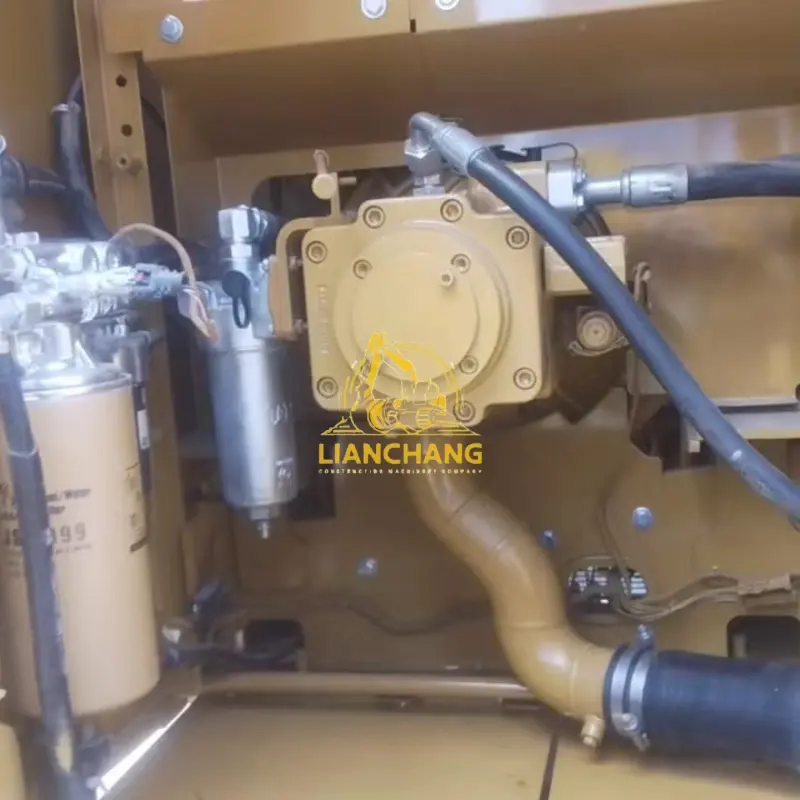

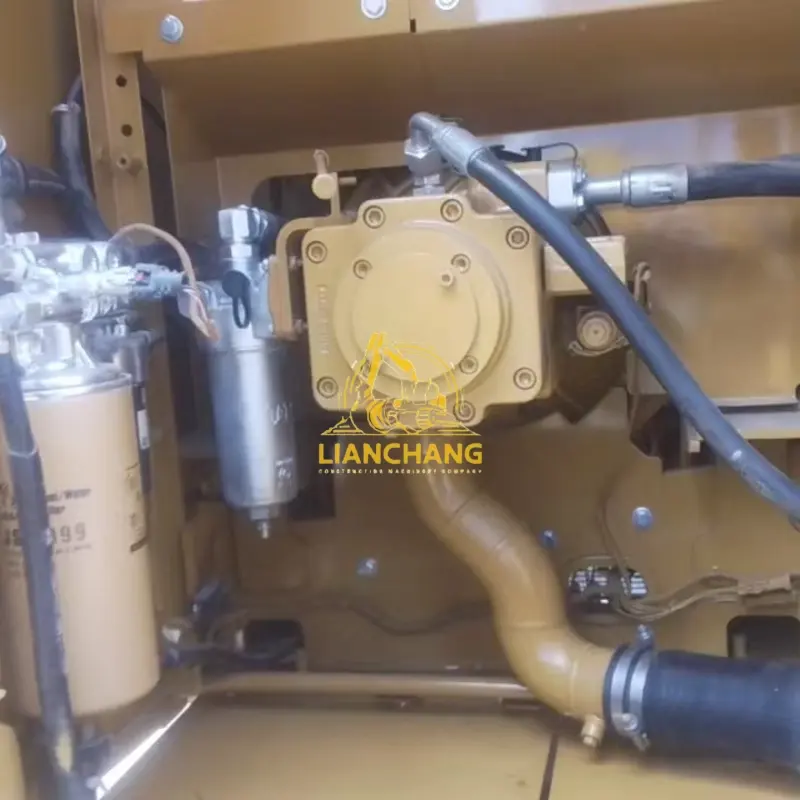

Maintenance, maintenance costs are expected to be reduced by up to 20% compared to the 320 D2. (Savings based on 12,000 hours of machine work.) ) Perform all routine maintenance work on the ground. Check the engine oil level quickly and safely using the new engine dipstick near the ground; Fill and check engine oil at the top of the machine with an easily accessible second dipstick. The filter life and maintenance intervals of the excavator are tracked through a monitor in the cab. Replace all fuel filters after 500 hours of synchronization. The new intake filter with pre-filter is expected to operate for 1,000 hours – a 100% longer service life than the previous filter.

The new hydraulic oil filter provides better filtration performance, and the reverse discharge valve keeps the oil clean when the filter is replaced, and the replacement interval is up to 3000 hours, for a longer service life. 50% longer than the previous filter design. The new high-efficiency electric cooling fan operates only when needed and can be reversed, eliminating debris on the core. The S · O · SSM port is close to the ground, simplifying maintenance and allowing quick and easy oil sampling for analysis.

Safety, integrated with the standard 2D E-fence function at the factory, prevents any part of the excavator from moving outside the operator’s specified set point to avoid hazards and jobsite accidents. As a result, the machine can work safely under the building structure or near passageways with frequent personnel movements. Standing on the ground provides access to all routine maintenance points – no need to climb to the top of the excavator. The standard ROPS driving room meets the requirements of ISO 12117-2: 2008. Thanks to a smaller cab column, wide windows and a flat bonnet design, the operator has excellent visibility, whether inside the ditch, in each direction of rotation or behind the operator.

When the standard hydraulic lock lever is in the down position, it blocks all hydraulic and travel functions. Once activated, the ground stop switch will completely stop the fuel supply to the engine and shut down the machine. The right maintenance platform adopts a new design, allowing easy, safe and fast access to the upper maintenance platform; Maintenance platform ladder using non-slip type perforated plate to prevent skid.

| Fob Price: $56000 / Unit |

| Мин. заказ: 1 шт. |

| Bucket Capacity: 1.19m³ |

| Working Hours: 1356hours |

| Год: 2019 |

| Бренд: КАТЕРПИЛЛАР |

| Доставка: Морской фрахт / Сухопутный фрахт |